Home

Superlok South – Precision Instrumentation Fittings and Valves for the Gulf Coast

Superlok South isn’t your average distributor, we’re a dedicated supply partner for Gulf Coast operations that can’t afford leaks, delays, or second-rate parts. We specialize in high-performance Superlok® Instrumentation Fittings and Valves built for demanding pressure systems and corrosive environments, with a deep inventory ready to ship across Texas, Louisiana, Mississippi, Alabama, and Florida. Our team has decades of field-tested experience in the oil and gas industry, petrochemical plants, hygienic fluid processing facilities, and complex industrial installations. We know what it’s like when a system’s down and the clock is ticking – and we know how to help you avoid that in the first place. From start-up builds to critical repairs, we supply the kind of fittings that hold under pressure, align with spec, and arrive fast.

Swagelok®-Compatible and Ready to Work

Whether you’re managing high-purity lines in a food-grade operation or pressure-heavy chemical loops in a refinery, Superlok South has your back with precision-machined parts built to perform. Our fittings don’t just match the big brands — they exceed expectations when it comes to quality, interchangeability, and price.

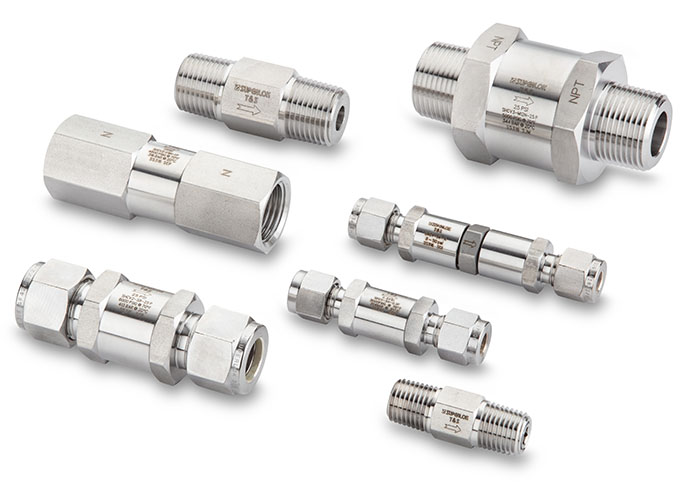

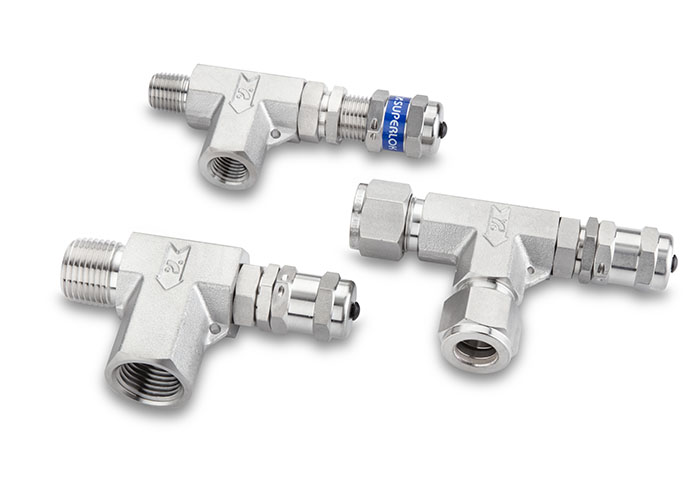

Every fitting and valve we stock is fully compatible with Swagelok® specifications — from compression fittings and double ferrule connectors to ball valves, bulkhead unions, and tube caps. We carry thousands of part numbers designed for seamless interchange with existing infrastructure. No surprises. No retooling. Just clean, dependable fitment you can trust.

Our clients include major oilfield service providers, chemical processing plants, clean-in-place sanitation systems, original equipment manufacturers, and maintenance contractors who need reliable inventory without inflated lead times or bloated pricing. With Superlok South, you’re getting the same dimensional tolerances, the same materials, and the same pressure ratings — without the premium markup.

Every Superlok fitting we supply is made from 316 stainless steel or other corrosion-resistant alloys chosen for their strength and reliability in extreme environments. These materials don’t just resist pitting and rust — they hold steady in systems exposed to saltwater, high-pressure steam, aggressive chemicals, or continuous cycling.

Whether you’re maintaining process lines in offshore platforms or building sanitary-grade systems for hygienic fluid processing, you need components that won’t fail when it counts. Superlok South provides those components, with fast shipping and support that understands your workflow.

Built for Pressure Systems, Backed by Inventory

Industrial fluid handling demands consistency — and consistency starts with fittings that deliver the same performance every time. That’s why we stock a wide selection of instrumentation fittings and valves engineered for pressure systems operating under the harshest conditions. We’re not just filling shelves – we’re anticipating needs.

From temperature swings and vibration to harsh media and continuous flow, our inventory is tailored to perform where it matters. And if you’re not sure what part you need, we’ll help you identify the exact match and get it out the door the same day.

We’re here to make sure you never have to second-guess your fittings supplier. Our customers stay with us because we deliver the real-world reliability they need — without the headaches. We answer calls. We quote fast. We ship immediately. And we know your system like we built it ourselves.

Need 316 stainless steel fittings for a high-pressure line? Need corrosion-resistant valves that won’t seize up in your CIP loop? Need a cross-brand alternative to Swagelok® that doesn’t sacrifice quality?

You’re in the right place.

We serve the entire Gulf Coast corridor - Texas, Louisiana, Mississippi, Alabama, and Florida - with fast shipping and responsive support.

Our founder's background with DK-LOK gives us unique insight into the instrumentation fitting market and what customers truly need.

We provide cross-referencing and quoting for Swagelok® part numbers - helping you get the right compatible product the first time.

Superlok fittings and valves meet the highest standards with certifications including ISO 9001, TUV, Lloyd's Register, DNV, and more.

Need a part after hours or over a weekend? Give us a call – we’re known for going the extra mile.

163 Ridgewood Dr., Daphne, Alabama 36526

Superlok fittings are essential components in the pulp and paper industry, where robust and reliable fluid handling systems are critical for efficient and uninterrupted operations. These fittings are used in various applications, including chemical processing, steam lines, and instrumentation systems.

The pulp and paper manufacturing process involves harsh conditions, such as high temperatures, high pressures, and exposure to corrosive chemicals. Superlok fittings are engineered to withstand these challenging environments, providing secure, leak-proof connections that ensure the safety and reliability of the entire system. Their superior surface finish, precision engineering, and ease of installation contribute to minimizing maintenance needs and operational downtime.

With industry-recognized certifications like ISO 9001 and others, Superlok fittings are trusted for their high quality and performance, making them an ideal choice for enhancing efficiency and safety in the pulp and paper industry.

Superlok fittings are essential components in the aerospace industry, where precision, reliability, and safety are paramount. These fittings are utilized in various critical applications, including fuel systems, hydraulic systems, and instrumentation lines. The aerospace environment demands components that can withstand extreme temperatures, high pressures, and rigorous vibrations.

Superlok fittings are engineered to meet these stringent requirements, offering exceptional surface finish, ease of installation, and superior machining technology. Their reliability is backed by numerous industry certifications such as ISO 9001, NUCLEAR N STAMP, and others, ensuring that they perform flawlessly in the most demanding conditions. By choosing Superlok fittings, aerospace engineers and manufacturers can ensure optimal performance, safety, and longevity of their systems.

Superlok fittings play a critical role in the biotechnology industry, where precision, cleanliness, and reliability are of utmost importance. These fittings are extensively used in laboratory and production environments for applications such as fluid transfer, instrumentation, and process control.

In biotechnology, maintaining contamination-free and leak-proof connections is essential to ensure the integrity of biological samples and processes. Superlok fittings, known for their superior surface finish and precision engineering, provide secure and reliable connections that prevent leaks and contamination. Additionally, their easy installation and maintenance reduce downtime and increase efficiency in biotech operations.

With rigorous industry certifications, including ISO 9001 and high purity standards, Superlok fittings are trusted to meet the stringent requirements of biotechnology applications, ensuring optimal performance and safety in critical processes.